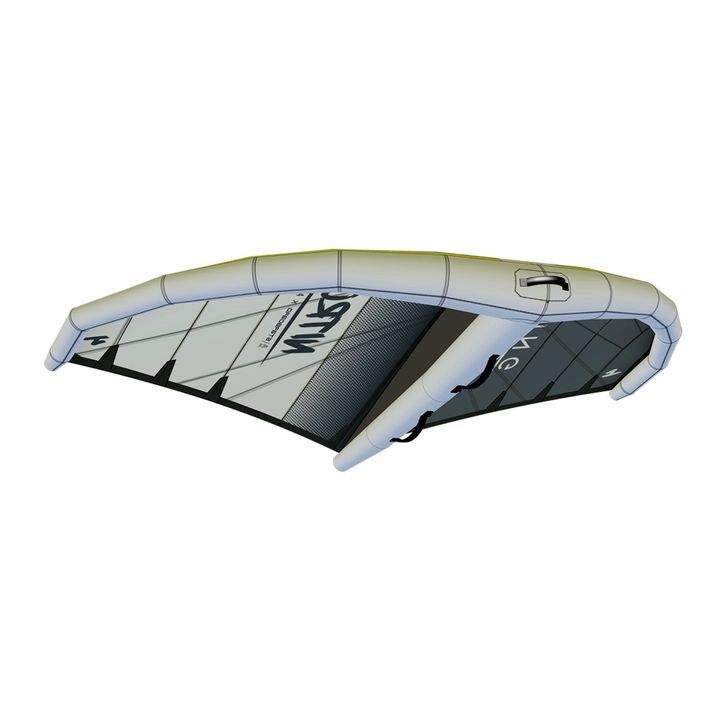

Airush Freewing Nitro

IN A NUTSHELL...

The Nitro Wing features cutting-edge designs with innovative materials to offer wingfoilers and wingsurfers a no-compromise, high-performance wing. This ultra-responsive, lightweight and super durable wing delivers instant, smooth power for wingfoiling and windsurfing. It feels like it’s 1m larger but controls like it’s 1m smaller, exactly like nothing else.

Design details

The Nitro Wing features cutting-edge designs with innovative materials to offer wingfoilers and wingsurfers a no-compromise, high-performance wing. This ultra-responsive, lightweight and super durable wing delivers instant, smooth power for wingfoiling and windsurfing. It feels like it’s 1m larger but controls like it’s 1m smaller, exactly like nothing else.

The FreeWing Nitro is mind-bogglingly better, but why?

We’ve combined over 20 years of kite and wing design experience with tomorrow’s technology, to create the new Nitro Wing.

Our unique ideology on composite materials means we have spent years chasing responsiveness, light-weight and durability in a single product, and the Nitro is the best example of this yet.

The key to the Nitro Wing is ultra PE frame space (read more about the HOOKIPA below) which combines our absolute cutting-edge Ultra PE high-pressure leading edge and strut with our proven Ultra PE load frame.

Introducing Hookipa Ultra PE – by Challenge Sailcloth

Developed in conjunction with Challenge Sailcloth, this unique woven composite is the result of exhaustive development and testing, to nd the optimum balance between responsiveness, lightweight and long-term performance.

Traditional Ultra PE materials relied on a high percentage of films, coatings or glues to stabilize the material. The outcome of this was that these materials were strong, but either needed complicated seam constructions, had a limited amount of structural ber (for their given weight) or had inconsistent strength and distribution throughout the fabric.

Hookipa Ultra PE takes a reliable woven structure and supercharges the material through the use of Ultra PE instead of traditional polyester fabric.

The high amount of material in the composite that is structural, has allowed us to optimize all areas of the construction resulting in that beautiful blend of responsiveness, lightweight and durability.

Incredibly, the most high-performance fabric we have ever developed, comes with a reduced environmental impact, where Hookipa Ultra PE is made up of 48% recycled content by weight.

Understanding Ultra PE

* Ultra PE Fiber is a super-strong ultra-high molecular weight polyethylene (UHMwPE) ber that offers maximum strength with minimum weight.

* Ultra PE has extremely long molecular chains that transfer load more effectively. So it‘s stronger at the same weight or lighter at the same strength than alternatives. In a direct comparison to polyester, it is up to 32x Stronger.

* Ultra PE fiber is 15x stronger than steel at the same weight and 2x lighter than Carbon Fiber.

* As well as its extraordinary strength, Ultra PE excels in cut and abrasion resistance and has a high resistance to UV.

* Ultra PE fiber is so light that it floats on water.

* Stiff does not mean fragile, Ultra PE also has very high ductility – It can absorb a lot of energy before it breaks.

Understanding the characteristics of this material is the key to the responsiveness of the NITRO, the process if inflation places a higher tension on the fabric and you feel that immediately. This does not stop at the strut and leading edge but is integrated into the canopy through the Ultra PE load frame.

Tech specs

Understanding the characteristics of this material is the key to the responsiveness of the NITRO, the process if inflation places a higher tension on the fabric and you feel that immediately. This does not stop at the strut and leading edge but is integrated into the canopy through the Ultra PE load frame.

Ultra PE Load Frame

This technology continues into the canopy where Ultra-high, modulus yarns carry the primary load of the canopy, preventing stretch and increasing long-term performance. This enables us to minimize or completely remove the heavier fabric and utilize the ballistic high-modulus web fibers instead, thus increasing strength and minimizing weight. These yarns are integrated through reinforced taping that allows them to elongate under extreme load, absorbing most of the forces that would occur under shock loading.

- Ultra-Responsive, high pressure leadinf edge and strut.

- Load Frame stabilizes and support high tension canopy.

- 30% Lighter than aa traditional wing with greater stability.

HIGH PRESSURE LEADING EDGE

While able to run 30 – 40% more leading edge pressure, this creates a stiffer structure and ultimately allows us to run a thinner leading edge.

LOAD FRAME SUPPORTED CANOPY

Utilizing the same Ultra PE primarily Fiber as the Leading edge and Struts, the load frame carries much of the primarily load running through the canopy. This prevents the the canopy cloth from over stretching and losing performance. This also increases esponsiveness by creating a more locked in shaping into the canopy.

THINNER LEADING EDGE

* Reduces the drag on the wing, when the wing is flagged out while riding or down winding. This is especially important in more offshore wave conditions to help keep the rider on the wave face.

* Allows a higher angle of attack when going up wind or travelling at higher speed.

REDUCED WEIGHT

* The Hookipa Ultra PE fabric is 25% lighter than traditional Dacron leading edge materials.

* The reduce diameter structures and optimized details result in an overall weight saving of up to 30%.

HIGHER TENSION CANOPY

The higher tension leading edge increases tension which improves the stability of the wing, early planning and responsiveness.

THINNER TIPS

Thinner tips reduce the oscillation of the wing when the wing is in neutral. This makes the NITRO easier to control when the wing is flagged out.

HIGH PRESSURE LE AND STRUT

The biggest combined benefits of the Ultra PE is the ability to run higher pressure without sacrificing longevity. This higher tension leading edge creates a much more responsive frame that can be loaded before jumping, pumps incredidibly well and responds quickly to rider input.

- 3m - 20-40kts - 11psi - 258cm span - 1.42kg

- 4m - 16-32kts - 10psi - 285cm span - 1.64kg

- 5m - 12-26kts - 10psi - 298cm span - 1.95kg

- 6m - 9-22kts - 9psi - 286cm span - 2.17kg